How to care for and maintain the hydraulic ram, ram-end roller and hose-burst valve on the Simpro Multi-Tip bin lifter.

Overview

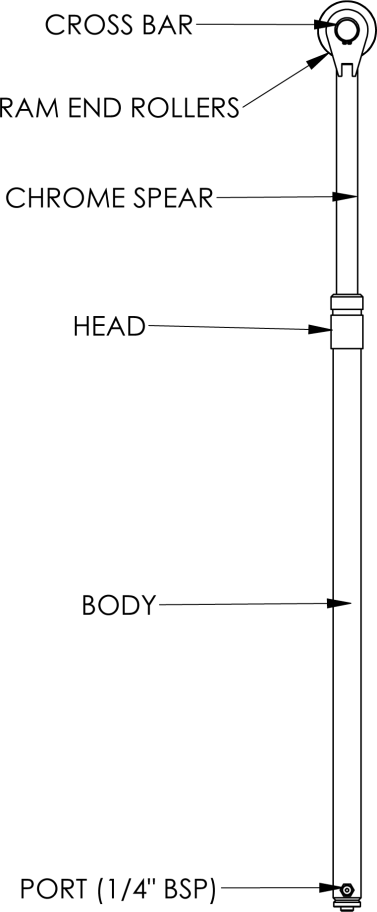

Multi-Tip bin tippers use a single-acting displacement-type hydraulic ram, which is very reliable, but also easy to service should the need arise. There is no piston, just a seal in the head which seals onto the chrome-bar spear.

A ram end roller is fitted to the end of the spear, which transfers the power of the ram into the lifting chain.

Removal and refitting

- Lower the cradle fully, then remove the upper and lower ram covers.

- Undo the hydraulic hose fitting at the bottom of the ram.

- Disconnect the chain from the adjusting bolt and tie it to the mesh guard with string or wire to stop it falling down inside the mast.

- Undo the screws holding the alignment plate, flip it up against the mast face and slide it out to one side.

- Lift the ram out of the bracket, carefully feeding the port through the cutouts in the mast and bracket.

Refitting is a reversal of the above procedure, with attention to the following points:

- Extend the ram fully before refitting.

- Ensure the rams is centred between the rams stops before tightening the alignment plate screws.

Dismantling and servicing

- Hold the ram body horizontally in a vice, with the roller end slightly higher.

- Pull the chrome-bar spear right out of the ram body, and lay aside, taking care not to damage the chrome surface.

- Take the ram body out of the vice, and pour the small amount of remaining oil into a suitable container for disposal.

- If the seal has been leaking, pick it out of its groove near the end, using a small, sharp screwdriver. It is very difficult to remove without damaging it, and it is usually best to just stab it, pull it out, and replace it with a new one.

- If there is a pinhole leak in a weld, it is generally best to fit a complete replacement ram body, and return the faulty one to Simpro for repair. If this is not feasible, mark the location of the hole, and grind a groove at least 3mm deep, and 10mm each side of the hole. If possible, weld using MIG or arc welder. If a welder is not available, it may be brazed, but difficulty may be experienced because of oil contamination. The seal will need to be replaced, if the hole is in the “head” weld.

- The ram body should be cleaned with degreaser, and then blown out with compressed air.

- To reassemble, fit a new seal (#R44035), if necessary. Smear oil on the seal and inside the head. Wipe the chrome bar carefully, and then fit it back into the ram body, using a twisting action as it goes through the seal.

Ram End Roller

The ram end roller is fitted to the end of the ram spear, and transfers the power of the ram into the lifting chain. It is very reliable and requires no regular maintenance.

Removal and refitting

- Lower the cradle to the ground, then remove the upper and lower ram covers.

- Disconnect the chain from the adjusting bolt and tie it to the mesh guard with wire to stop it falling down inside the mast.

- Remove the circlip on one end of the roller axle and push or tap it through until the roller can be extracted.

- When refitting, smear the inside of the roller liberally with grease, press the axle back through, and replace the circlip.

Hose-Burst Valve

Some models of Multi-Tip are fitted with a hose-burst valve, which automatically closes if the flow out of the ram exceeds approx. 10 litres/minute. This flow would normally only occur if there is a failure in the hydraulic system.

If the hose-burst valve closes for any reason, the hydraulic system must be repaired, then the ram extended slightly before it will reset itself.

Removal and refitting

On occasions the hose burst valve may become faulty and it may be desirable to remove the burst valve so that the machine can continue to function. The hose burst valve cartridge may be unscrewed from the port as per the video below.