How to correctly refit the Dumpmaster lifting chains into the wear strip grooves if they have become dislodged during transport.

The chains on a standard Dumpmaster bin-tipper are open ended, so the only tension in them is caused by the gravity force pulling down on the cradle. When the machine is lain down or put onto its side, the chains will go loose and can come out of their grooves in the top roller and the wear strip at the top of the machine. This has the effect of causing too much friction in the system so that the cradle will not lower when the lower button is pushed.

Procedure

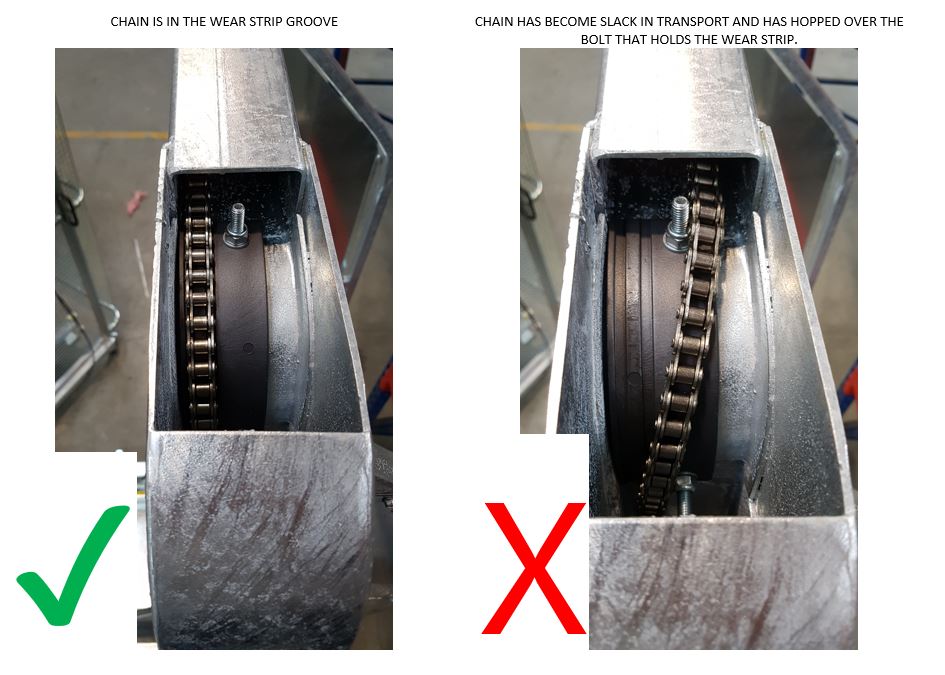

- Remove the covers at the top of the machine (the “top caps”) and you should be able to see the chains as per the image below.

- Using a screwdriver, pop the chains back into the chain grooves

- Replace the top caps.