How to change the tipping height on an adjustable model of the Simpro Multi-Tip bin lifter.

An optional extra that is built into some Simpro Multi-Tip models is the ability to adjust the tipping height of the bin tipper. This is a feature that can be requested from the factory at the time of order and is useful for the waste industry as it means that the machines can be adapted for different situations as equipment leases roll over etc.

Procedure

- Lower the cradle to ground level.

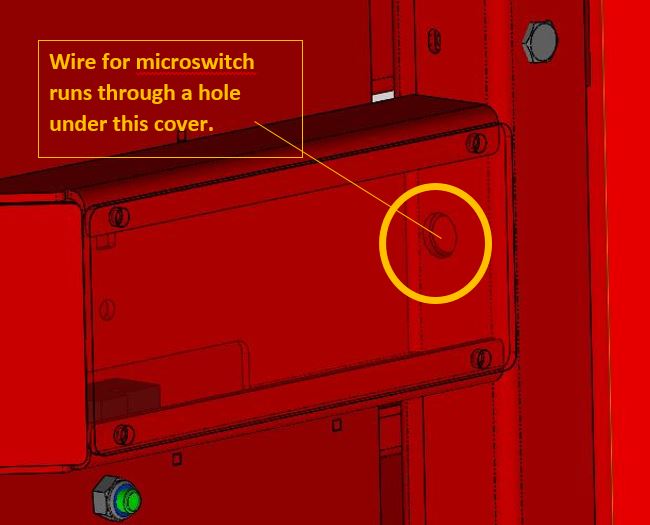

- Remove the switch cover on the tipping track support to expose the microswitch wiring in the tipping track guide. It will be easiest if you undo the wires to the microswitch now so that this wire can be redirected through the lowered position in the subsequent steps. (Top tip: take a photo of the wiring on the switch before undoing it so that you can put the wires back the same way later)

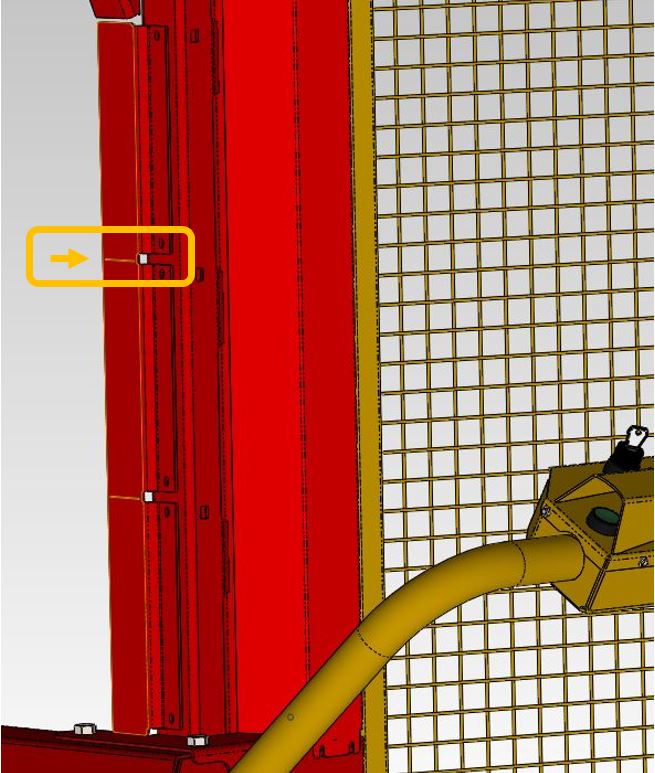

- Next you will need to remove a section of the roller guide that will be in the way of lowering the tipping track. Take a thin bladed grinder and cut away the track guide at the most appropriate pre-marked position. (If you are trying to lower the track by 300mm, then only one section will need to be removed and so on.)

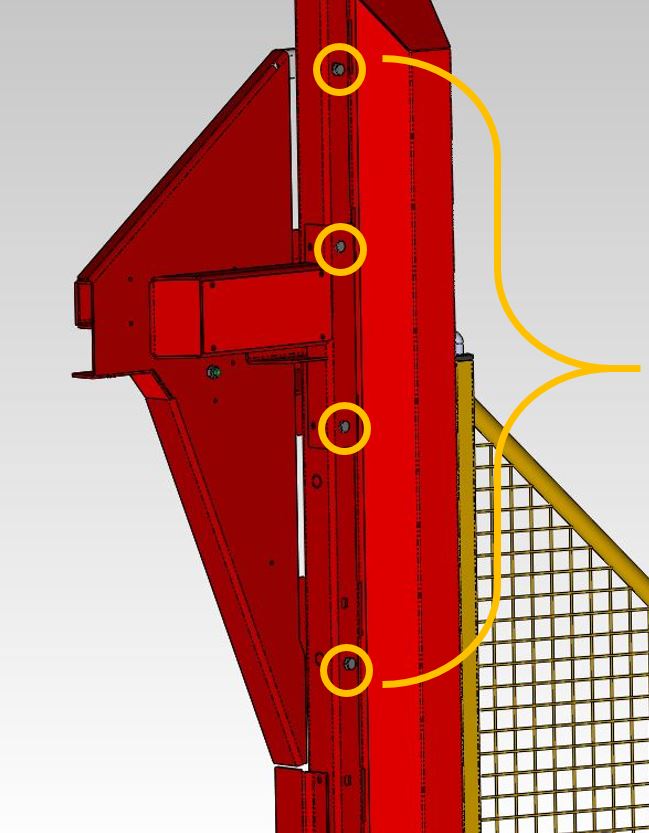

- Remove the tipping track guide by undoing the bolts that hold the guide frame to the upright members.

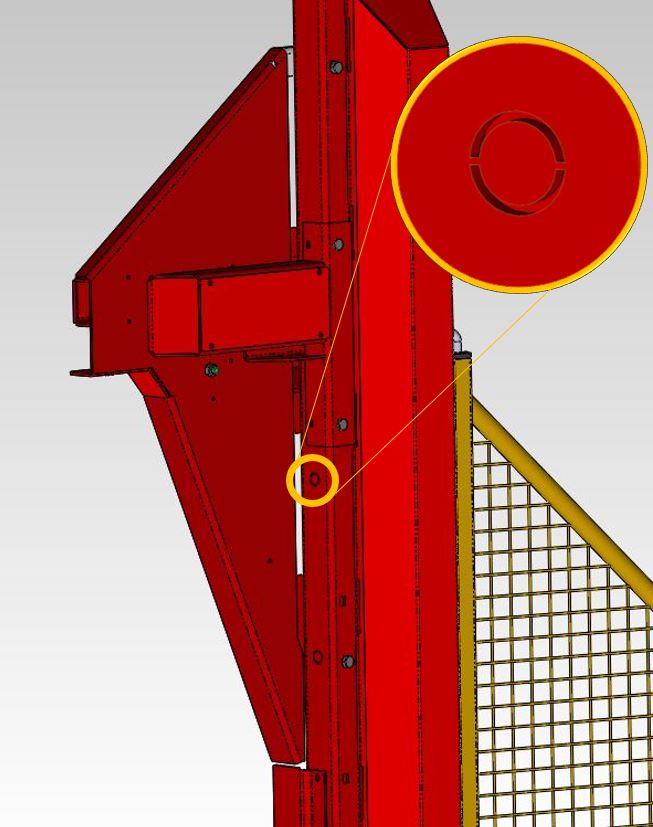

- Now you will need to knock out the plug that is filling the hole for the tipping track support to be refixed in the lower position. Take a punch and hammer and knock the pre-cut hole out. This hole is for the wire to the microswitch to run through.

- Once all the tipping track bolts have been removed, move the track down to the desired location and refasten.

- Re-run the wire to through the new hole and connect the wires to the microswitch again.

- Put the switch cover back on.

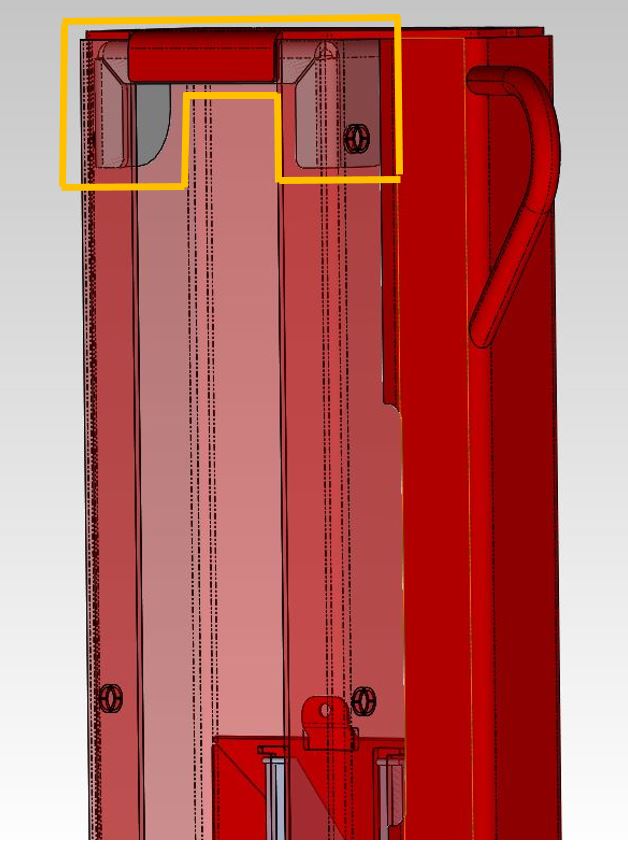

- Inside the top of the mast there is a ram stop bracket that arrests the ram if the microswitch fails or is damaged. This will need to be lowered by the same amount as the tipping track.

- Once again, there are holes that have been partially cut prior to powdercoating and these can be tapped out in the same manner.

- Use a touch-up aerosol can to repair any marks left from this process.

- Test functionality carefully to ensure that everything works as intended.